Detailed Description:

Detailed introduction to Heavy Hummer Crusher:

Rotor disk, driven under the motor, drive the hammerhead to do high-speed circular motion. Materials are carried into machine from the upper feeding inlet, crushing by the strike, impact, bump, and grind of the high-speed running hammerhead. After crushing, those materials with larger granularity than requirement hit the counterattack board for re-crush along the hammer tangent direction with the new materials, so that the coarse, medium and fine crushing all in one station, finally materials meeting requirement exclude from material outlet.Hammer Crusher set stone crushing and shape as a whole, with big feeding granularity and small outgoing granularity. Changing three-level crushing to first-level crushing, rotor speed is high, the hammer with great weight and durable service. It has advantages of large reduction ratio, great production, particles shapeliness, simple structure, easy maintenance, etc.Adopt new design idea. Comparing with the same type produces, it has larger production and higher qualified rate, shapeliness particles, lower energy consumption.

Enable to crush wet or dry tow forms material, can handle higher water content materials, not blocking materials.

The replacement of wearing parts is very convenient, and the maintenance cost is low;

This equipment can replace the primary, secondary crushing of traditional jaw crusher and impact crusher, thus reduce the equipment investment.

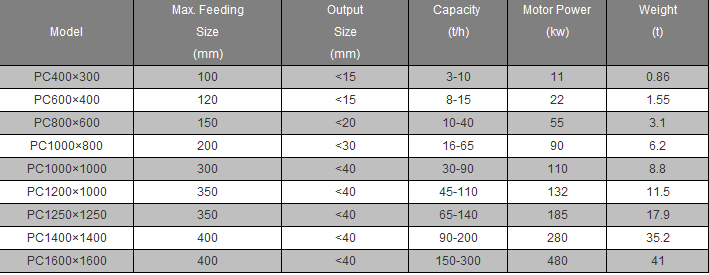

Technical parameters of the hummer crusher:

The working principle of the bummer crusher:

Note:if you want to know more about hummer crusher,please submit your requirements to us.We will contact you as soon as possible.Welcome to our company.We can manufacture equipments according your spscial requirements.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087