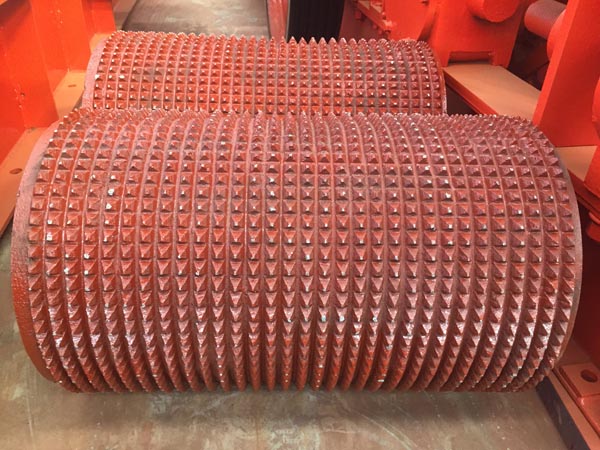

Product Introduction

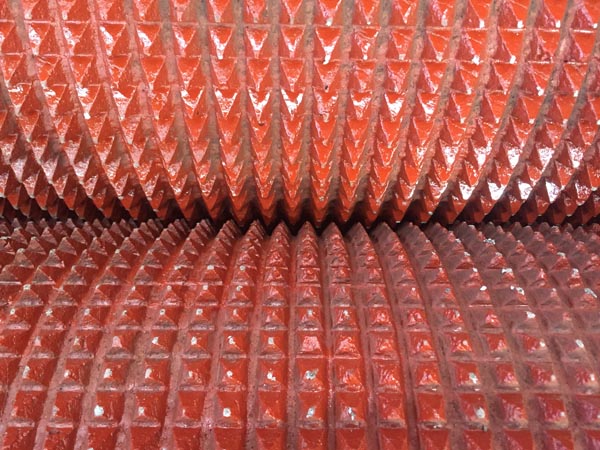

The Toothed Roll Crusher is applicable to the industries of coal, metallurgy, mineral, chemical and construction materials, and It is more suitable to crushing raw coal (included gangue) of big coal mine or coal separating plant. The electrical motor and speed reducer is connected by distance limited hydraulic turbo coupling, which prevents the dynamic overload and sensor overload for safe operation. The distance between the toothed rolls is adjusted by hydraulic and the bearing of the toothed rolls is centralized lubricated. It has the features of optimal designing of gear shape, the choice crushing between tension and cutting, high efficiency with low consumption, uniform production size

Toothed Roll Crusher is worked by making two toothed roll rotate oppositely under the action of two pulleys on two sides of crusher, which driven by one motor or some motors. Thus the materials reaching the required size fall and discharged automatically, while the ones larger than two toothed rollers still left to be crushed until they reach the required size.

1.Average discharging size without blocking up.

2. Automatically screening the materials after crushing.

3. High efficiency and low energy consumption.

4. Good flexibility and operational reliability.

5. Full-sealed design and no dust pollution.

6. Small vibration and low noise.

7. Removable shell which is convenient for daily maintenance and inspection of the machine.

Main technical parameters:

| Model | Feed Size (mm) | Discharging Size (mm) | Capacity (t/h) | Power (kw) | Weight (T) | Dimensions (L×W×H)(mm) |

| 2PGC450×500 | ≤300 | 15-125 | 30-60 | 22 | 3.4 | 2492×2200×758 |

| 2PGC600×750 | ≤600 | 15-150 | 60-100 | 30 | 6.9 | 3265×2780×1442 |

| 2PGC600×900 | ≤600 | 15-150 | 80-120 | 37 | 7.2 | 3265×2810×1442 |

| 2PGC900×900 | ≤700 | 15-200 | 100-160 | 60 | 13 | 3500×3300×1400 |

| 2PGC1250×1250 | ≤800 | 20-300 | 150-300 | 110 | 36.5 | 7980×5872×2200 |

| 2PGC1200×1500 | ≤800 | 20-300 | 200-500 | 150 | 55 | 8010×4900×2170 |

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087