Description of stone washing machine:

The products are mainly for the construction of highways, railways, bridges, tunnels high standards of engineering, used to wash aggregated rock of specialized equipment, with ease of movement, processing power, and clean high rate of savings in power and so on, compared with domestic like products.

Applicable to fine-grained and coarse-grained materials of the washing operation. Stone washing machine in the rational structure, convenient maintenance, handling a large amount of power, consumption is small, clean and high. Novel seal structure, the new shaft installed, adjustable septic tanks to ensure that the product efficiency, durability, cleaning, dewatering effect, and fine-grained features such as product stability.

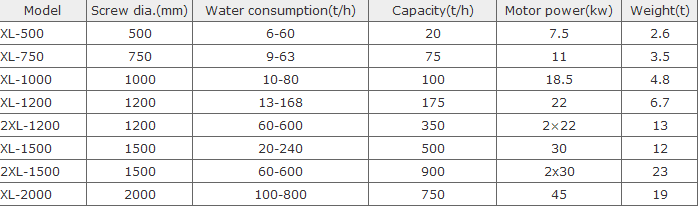

Specification of stone washing machine:

Working Principle of stone washing machine:

Firstly,the big size material is processed by the jaw crusher and reduced into shivers less than 20mm (for 3R66 pulverizer, the input size is less than 15mm). Then the materials are carried into hopper by bucket elevator, and is transported into the mainframe by the electro-magnetic vibrating feeder evenly and continuously for grinding. The mainframe is driven by the speed reducer through the central axis in the mill. The quincunx stand connected with the upper part of central axis, at the quincunx stand, rollers are set and by which the vibrating pivot formed. Below the quincunx stand and rollers there is shovel system. Materials are fed into the space between rollers and shovels when they are turning, and then be grinded by the pressure produced when rollers are turning, thus powder is made. The crushed powder is blown into the analytic engine on the upper of main frame by air current for divisional screening. The unqualified powders will fall into main frame for regrinding, and the qualified will enter the large cyclone collector. After separating and collecting, powders will be discharged through pipes, that is, finished products. After separation, air current is absorbed into fan by the upper pipe of the cyclone collector. The whole air current system is airtight, and it is operated under the negative pressure.

Full Service of Fote Machinery

1>.Pre-sale services

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

2>.Sale services

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

3>.After-sale services

To establish long term friendship, we will regularly pay return visit to customers.Supplying technique, building design, instruction, installation and debugging for free.

4>.We provide one-year warranty to make sure your machine runs consistently. We always offering lifelong services and provide spare parts for a long term,and repair main parts under right using for free in two years.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087