High Quality Teeth Roller Crusher Used For Coal

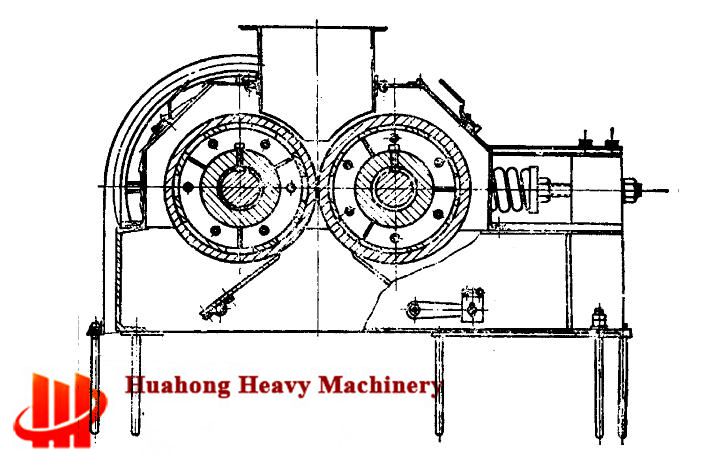

1.Brief introduction of double roll crusher:

Double roll crusher is also called roll crusher, two roll crusher, double teeth roll crusher etc. double roll crusher bite material into crushing area through roller friction, material was crushed by squeezing and fracturing of machine. When it is used in coarse crushing or crushing ratio increases, roller surface are usual teeth or groove in order to increase fracturing effect. Double roll crusher from HSM use high manganese steel casting roller surface which is through heat treatment. We firmly believe that roll crusher's quality depends on roller surface. We recommend double roll crusher firstly because of less quick-wear part which is only roller surface.

2.Application

3.Working principle of roll crusher:

Roll crushers have a theoretical maximum reduction ratio of 4:1. If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch. Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm). A crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particle, called the nip angle. The two rolls force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls.

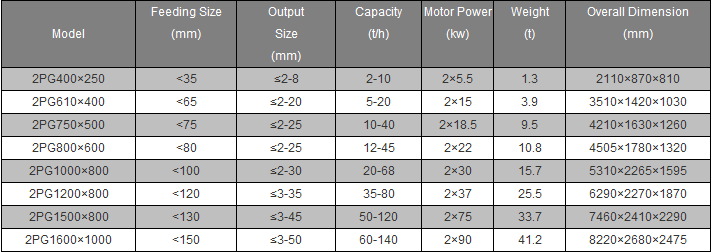

4.Parameters of roller crusher:

Note:The technical parameters above are just for your reference. If there is any change, all parameters and overall dimension are subject to operating instructions. Any questions please feel free to contact us.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087