The Working Principle of Jaw CrusherCurrent position:

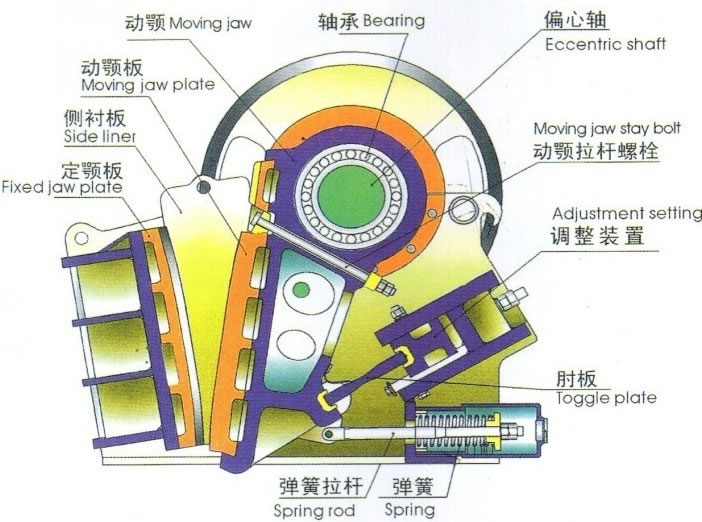

The work part of jaw crusher is two pieces of jaw plate, one is the fixed jaw plate, which is vertically (or the upper slightly extraversion) fixed in front of the body wall, the other is movable jaw board, gradient location, and with fixed jaw plate forming a crushing cavity (working cavity). Movable jaw board do a periodic reciprocating motion toward fixed jaw plate, sometimes separately, sometimes near. During their separating, material is feeded into the crushing cavity, and the finished products unload through the bottom; When they are approached, the materials between two pieces of jaw plate are squeezed, and then broken caused by bending and fracturing.According to the motion of the movable jaw board, jaw crusher can be divided into simple oscillating jaw crusher (simple pendulum jaw crusher), complex oscillating jaw crusher (compound pendulum jaw crusher) and integrated oscillating jaw crusher.Simple pendulum jaw crusher crushing principle:The moving jaw hangs on heart shaft so that it can swing from side to side. Eccentric shaft rotates, connecting rod to do reciprocating movement up and down, also do reciprocating motion drives the two pieces of thrust plate, pushing around moving jaw do reciprocating motion, crushing and discharging.This crusher adopts crank connecting rod mechanism, although have very big by the moving jaw broken reaction, while the eccentric shaft and connecting rod bearing is not big, so much on industrial made mainframes and medium-sized machine, used for crushing hard materials.In addition, this kind of crusher work, the trajectories of each point on the moving jaw is spindle as the center of circular arc, arc radius is equal to that point to the axis of the distance, the upper arc small, bottom arc, crushing efficiency is low, its broken than general for 3-6. Because of its simple movement, therefore calls simple swing jaw crusher.

Jane simple pendulum jaw crusher compact structure, small eccentric shaft, a bearing;Because of the moving jaw vertical displacement is small, processing material less excessive broken phenomenon, when moving jaw jaw plate wear small.

Compound pendulum jaw crusher crushing principle:

Upper jaw hanging on the eccentric shaft directly, as a connecting rod connecting rod, the direct drive of eccentric shaft, the lower end of the moving jaw hinge connecting thrust plate support after the frame of the wall.When the eccentric shaft rotation, the trajectories of each point on the moving jaw is a circular line of suspension point (radius) is equal to the eccentricity, gradually become oval down, more to the bottom, the partial the oval, until the bottom and the thrust plate connection point trajectory for arc line.Due to this kind of mechanical motion trajectory of each point on the moving jaw is more complex, so called complex oscillating jaw crusher.

Compound pendulum jaw crusher compared with simple pendulum, its advantage is: quality is lighter, less component, the structure is more compact, crushing cavity is good, the outside material block by uniform broken, to move the lower jaw introduced mandatory finished discharging, so the productivity is higher, than with the specifications of the simple pendulum jaw crusher; 20-30% higher productivity. Material block at the bottom of the moving jaw have larger rolling up and down movement, prone to cube shape discharge, reduce the flake like Jane in the pendulum product composition, product quality is better.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087