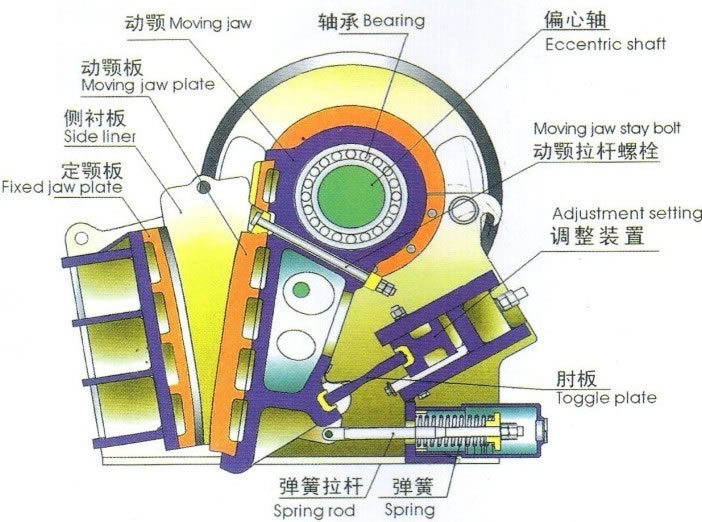

The work part of jaw crusher is two pieces of jaw plate, one is the fixed jaw plate, which is vertically (or the upper slightly extraversion) fixed in front of the body wall, the other is movable jaw board, gradient location, and with fixed jaw plate forming a crushing cavity (working cavity). Movable jaw board do a periodic reciprocating motion toward fixed jaw plate, sometimes separately, sometimes near. During their separating, material is feeded into the crushing cavity, and the finished products unload through the bottom; When they are approached, the materials between two pieces of jaw plate are squeezed, and then broken caused by bending and fracturing.

According to the motion of the movable jaw board, jaw crusher can be divided into simple oscillating jaw crusher (simple pendulum jaw crusher), complex oscillating jaw crusher (compound pendulum jaw crusher) and integrated oscillating jaw crusher.

The difference between simple oscillating jaw crusher and complex oscillating jaw crusher.

Jaw crusher can be divided into simple oscillating jaw crusher, complex oscillating jaw crusher.

Their operating principles are very similar, but the movement locus of movable jaw have bigger difference. Because the movable jaw of simple swing jaw crusher is hung on the supporting shaft, when it make reciprocating motion, the trajectories of each point on the movable jaw is circular arc, and the horizontal route is from big top to small bottom, and the bottom of the movable jaw (row ore mouth) is the largest.

Because the ore blocks falling into ore crushing cavity on the top are often so big that they can not meet the necessary amount of compression, they can be broken only after crushed many times repeatedly.

Crushing load is mostly concentrated in the lower part of the crushing cavity and the jaw didn't work uniformly, which reduces the crusher production capacity. At the same time the vertical stroke of this crusher is small, with small grinding effect and slow row ore speed. But the jaw plate's wear is lighter and over crushing products is less. Due to complex oscillating jaw crusher's moving jaw is also connecting rod of crank-link mechanism, under the drive of eccentric shaft, the trajectory of points in the moving jaw is approximate elliptic, the ovality is from big top to small bottom and its top part is approximate circle. This crusher's horizontal stroke is just the reverse of simple pendulum jaw crusher, the upper part is big while the lower part is small, the upper horizontal stroke is about 1.5 times that of the lower so that it can meet the required amount of compression crushing large ore in the upper crushing cavity. At the same time, the moving jaw vertical stroke is larger than the horizontal stroke, especially the row ore mouth, its vertical stroke is about 3 times of horizontal stroke, which is conducive to row ore and increase production capacity. Practice shows that in the same conditions, the production capacity of compound pendulum jaw crusher is about 30% higher than simple pendulum jaw crusher. But the jaw plate wear fast, the product is seriously over crushing.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087