Jaw crusher application range is introduced:

Jaw crusher is used for mine, smelting, building material, highway, railway, water conservancy and chemical industry, etc all kinds of ores and large materials in medium size crushing, the broken material maximum compressive strength of 320 mpa, jaw crusher in mining, building materials, construction and other departments are mainly used as coarse crusher and crusher.

Classification of jaw crusher:

According to the inlet width size is divided into large, medium and small three, inlet width is greater than 600 mm for large machines, feed port in 300-600 - mm width for medium-sized machine, feeding mouth width is less than 300 mm for the minicomputer.

Working principle of the jaw crusher:

Jaw crusher are main structure frame, eccentric shaft, pulley, flywheel, hubei, side guard plate, bracket, bracket in the back seat, adjustable gap screw, reset spring, fixed jaw and movable jaw plate, etc, the bracket also have insurance effect.

This series of jaw crusher broken way for dynamic JiYaXing, motor drive belt and pulley, through the eccentric shaft to move up and down movement of hubei, when moving jaw rises bracket and dynamic Angle between hubei, thus promote the moving jaw plate to the fixed jaw plate, at the same time the material will be squeezed, rub multiple crushing, grinding, etc. When the moving jaw downward, bracket and dynamic Angle between hubei decrescent, dynamic jaw plate under the action of rod and spring away from fixed jaw plate, now broken material from crushing cavity mouth eduction, as the motor turns continuously broken mobile jaw for periodic crushing and discharging, realize batch production.

Jaw crusher performance characteristics:

1. The crushing cavity depth and no dead zone, to improve the ability to feed and production;

2. The broken than big, product size uniform,

3. The gasket type discharging mouth adjusting device, convenient and reliable, the adjusting range is big, to increase the flexibility of equipment;

4. Safe and reliable lubrication system, parts easy to change, small maintenance workload;

5. Simple structure, reliable operation, low operating costs.

6. Equipment and energy saving: stand-alone energy saving 15% ~ 30%, and the system energy saving more than double;

7. Discharging mouth wide adjustment range, can meet the requirements of different users;

8. Low noise, little dust.

Jaw crusher operation procedures:

(1) of the normal operation of crusher before continual production.

(2) to be crushed material should be evenly to join the crusher cavity, should avoid to lateral loading or loading with, in order to avoid unilateral overload or withstand overload.

(3) the normal work, the rise of temperature of the bearing should not exceed 30 ℃, the highest temperature should not exceed 70 ℃. More than the temperature, should immediately stop, find out the reason and ruled out.

(4) parking before, should first stop feeding, after being broken cavity material completely discharge, may shut off the power.

(5) broken, such as parking caused by crushing cavity block material, shall be immediately shut off the power to stop operation, after crushing cavity clean material, before starting again.

(6) jaw end after wear, adjustable head use.

(7) crusher use after a period of time, adapter bushing should be loose and damage the machine.

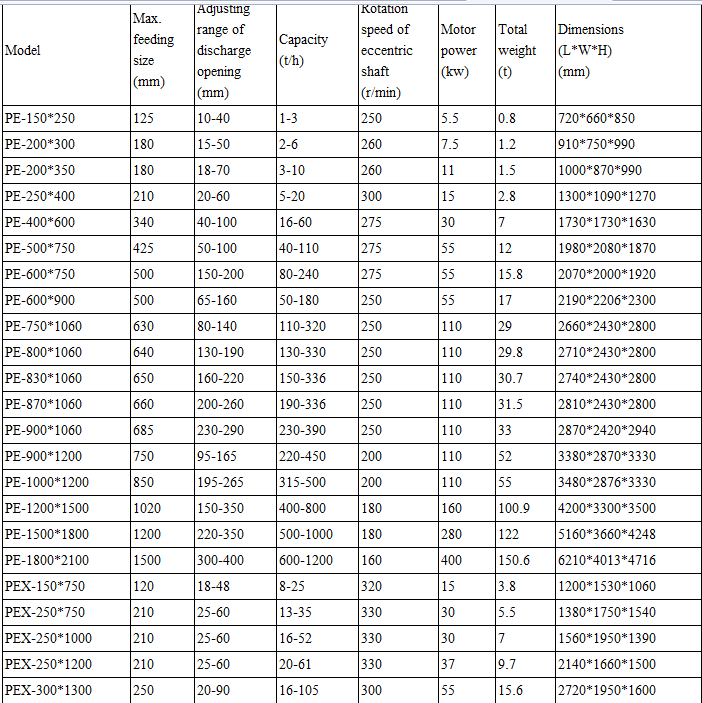

Jaw crusher specifications and performance parameter list:

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087