CE,CQC,ISO etc Quality Authentication Energy Saving Ball Mill,Processing Machine,Milling,Ball Mill Supplier,Rock Ball Mill in Zhengzhou Huahong Mining Machinery Equipment Co.,Ltd

Working Process of Energy-saving Ball Mill:

Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

Working Principle of Energy-saving Ball Mill:

Energy-saving Ball Mill is an essential recrushing equipment. Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

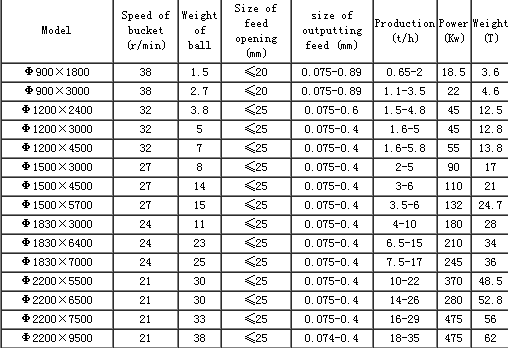

Technical Parameters of Energy-saving Ball Mill:

Note:if you are interested in the ball mill.Please submit your requirements to us.we will contact you as soon as possible,we can manufacture equipments according to your special requirements.Welcome to our company to know more about us.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087