JC Jaw Crusher Overview

Type:Primary Crusher

Feed Size:425mm-1250mm

Capacity:50t/h-1500t/h

Materials:River stone, gravel, granite, basalt, minerals, quartz, diabase, etc.

Applications:Mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

Compared with traditional jaw crusher, JC series Jaw Crusher pay more attention to the details. Adopts high-strength material, first-class manufacturing process, the series leads to the advantage of excellent-strength structure, reliable equipments, higher crushing ratio, bigger capacity and lower cost.

JC Jaw Crusher Features:

1.Sturdy Structure

Two kinds of Frames: Welded and Packaged. Usually, Small and medium sized model adopts welded, large model adopts packaged.Welded frame adopts wide transitional round edge, significantly reducing the stress concentration, ensure the frame under equal strength. It owns the features of good impact resistance and low failure rate, bears same pressure, etc.Packaged frame uses advanced modularization, no-welding frame structure design, high endurance strength and reliability. The whole set assembling design is convenient for the transporting and installation, especially suitable for installation of underground mine shaft, high altitude mine, as well as other narrow and difficult transporting place.

2.Extraordinary Cavity Design

Symmetrical V-shaped cavity design, high inclination-angle of the toggle, big stroke and reasonable speed, allows a bigger feeding size, higher capacity, uniform particle size and lower wearing of the plate.

3.Long Working Life of the Heavy-duty Movable Jaw Assembly

Heavy-duty Movable Jaw Assembly adopts heavy-duty eccentric shaft, high quality heavy-load rolling bearings and finite element software optimized movable jaw plate ensuring impact resistance and high stability of moving jaw assembly; labyrinth seal and centralized lubrication system guarantee the bearing lubrication oil is not contaminated and lubrication becomes more convenient. Therefore the assembly can have a long working time and stability.

4.Shield Design for the Movable Jaw

Heavy shield is installed above the movable jaw to avoid the material impact. It can effectively protect the movable jaw and its internal bearing from damaging.

5.Overall Bearing Support

Overall cast steel bearing support fully compatible with the rack, avoiding the combined bearing support has a unnecessary radical load on the bearing during the fastening process, making the bearing to run more smoothly.

6.Convenient Particle Size Adjustment

JC series Jaw Crusher adopts mechanical or hydraulic adjustment for the discharge range, compared with shim adjustment, double wedge adjustment operations is simpler, secure, fast, and saves more downtime.

7.Integrated Motor Installation

Integrated installation of motor seat and frame can not only save installation space, reduce the length of v-belt, but also can prolong v-belt working time, since the frame, motor seat, synchronous move of motor, adjustable motor seat bring v-belt tension adjustment.

8.Vibration Absorption Design

Crusher fixed by rubber vibration absorption device, which can effectively absorb vibration peak, while allow the vertical and longitudinal displacement of the crusher, thus reducing the impact on the foundation.

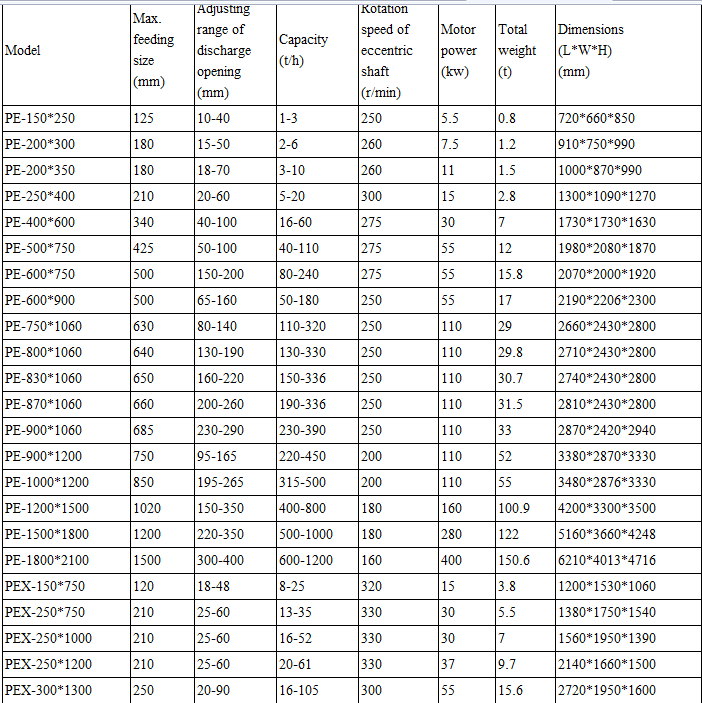

JC Jaw Crusher Technical Data:

Note:If you are interested in the JC jaw crusher,please submit your requirements to us.Welcome to visit our company.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087