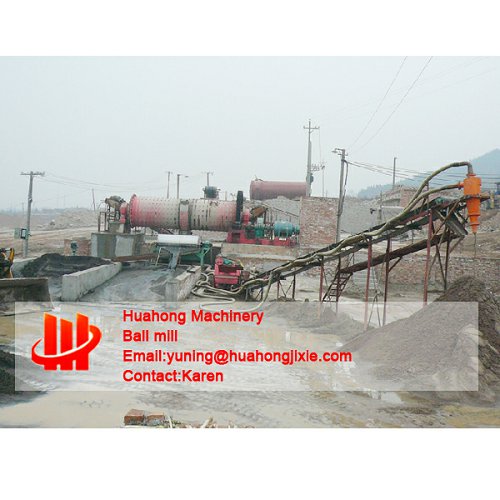

Cement ball mill production line

The photo above show good performances when onsite running for one of our clients.Cement mill also called Raw materials mill special designed for cement.Related type like Coal mill,Lattice type mill,Energy saving ball mill,Overflow ball mill are specail for different material.

Cement mill introduction:

Cement mill also named as ball mill, raw material mill, material grinding mill and clinker mill, is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material,fertilizer, ferrous metal, nonferrous metal and glass ceramics, and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Cement mill is composed by the feeding device, discharging device, rotary device, driving device(including reduction gears,small transmission gear, electrical machine, electronic control) and some other main components. The hollow shaft is made by the use of steel castings, the liner is detachable, rotary gear is cast with hobbing, the internal of cylinder installing with wear liner, which has a good abrasion resistance. This kind cement grinding machinery is stable to operate and reliable to work.

Cement mill is one of the important cement grinding equipment, it is the key equipment of regrinding materials after the materials were broken. The cement mill plays an indispensable role in the cement production line and in the cement production process flow. It is widely used in the cement and silicate, newly building materials, refractory matter, chemical fertilizer, the dressing of black and non-ferrous metal, glass-ceramic and other industries.

Hotline: 0086-371-67898087

Hotline: 0086-371-67898087